Finetuners

Hi, I recently just had a fix with my fine tuner on the E string, the loop was too sharp and so my E strings were constantly breaking. I brought my violin to the shop and the luthier switched the fine tuner from needing a loop end string to a ball end, and from an integrated fine tuner to a loose fine tuner. Other than having to now buy ball-end E strings, is there a real difference other than the look of the out of place integrated fine tuner?

Replies (14)

Oh yeah. I can't go without fine tuners, but I need good pegs too.

(and now shamelessly hijacking this topic!)

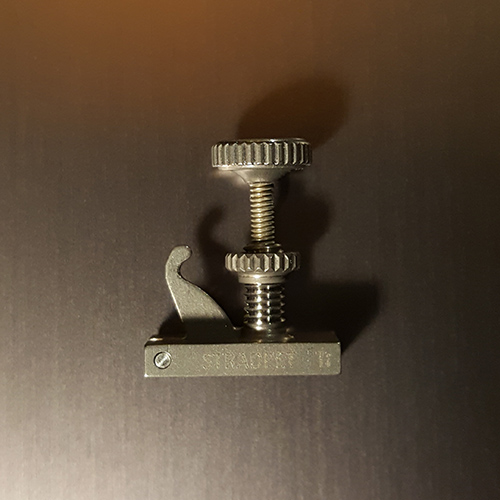

I got one of my violins a couple of Christmas presents: Titanium chinrest brackets and a titanium fine tuner.

The fine tuner (which is what's relevant to the topic) weights 1.9 grams. The one I had in previously (also Hill style) weights 3.4 grams, so it's a pretty big difference in weight.

I don't want to say there was a noticeable difference, ...but I think there was a difference! It was very, very slight, but I think some frequencies sounded a bit warmer, more resonant.

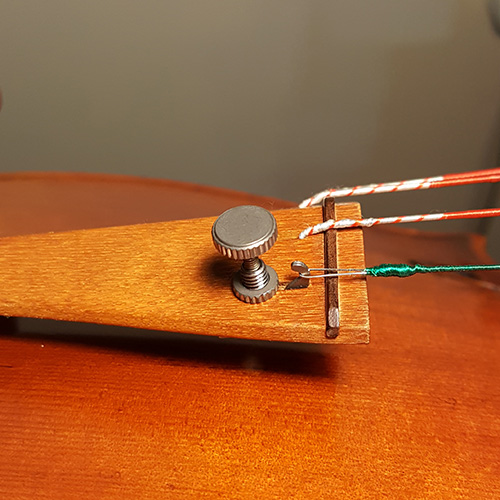

The model I got holds the string really low, almost to the fret on the tailpiece. It came with a little plastic guard for the string loop but I file the edges on the hook and put the string loop on the hook itself.

Questionable negligible improvement in tone or not, it's titanium, so it's fancy and different and cool!

Merry Christmas everyone! (or whatever you celebrate)

:)

What??? You threw away the little plastic guard?? And lost the ability to spend hours and hours and hours helplessly trying to put it on? And of course the hours of fun trying to find it in the carpet.

While I used loop finetuners, I never had trouble with those. I always had trouble making the loops to open wide enough to go around the tuner though

Hehe, no I didn't throw away the little plastic thing ...yet, but I am amazed such thing even exists! Couldn't they put the resources that went into that into making sure the hook was rounded and smooth instead?

Can a ball-end E with a hole in place through the ball be generally used on a single-prong loop fine tuner - that is, is the hole wide enough to go over the prong? If this can be done there should not be the problem you can get with a loop end.

What I have in mind is a ball-end Pirastro Obligato Gold E coupled with a Hill-type single prong fine tuner, such as either of those mentioned by Fox.

The little plastic guard is quite useless because, apart from the discomfort of its use, it will be cut by the string loop in a very short time.

Maybe might work if you change strings weekly.....

Round off carefully the edges of the hook is the key.

So why are the edges not rounded by the manufacturer?

I have never figured out as well.

Probably to keep down the costs of production (although some fine tuners cost quite a lot!!) or to provide work for violinmakers... :-)

.

...E strings last too long, they want to make sure you have to get a new one frequently. ;)

Trevor, I tried that (putting the single prong through the hole in the ball). The single prong is curved and prevents the ball from sliding all the way down (in fact the ball only goes down slightly more than the ball's width). Besides looking jerry-rigged, I felt that the forces would be working against success. I like the challenge of the little plastic thingies, just as much as I like using technical terms.

Thanks Bob. In view of that useful information I think I'll stick with the very short arm traditional lever Wittner I've been using for a long time.

On a related issue, I believe there is an unintentional smoke 'n' mirrors issue when it comes to after-length. To be sure, the ideal after-length, with the required resonances, can easily be calculated, but would only apply to theoretically ideal strings and set-up, which of course do not exist. The closest you could get to the theoretical in reality would be with either a set of plain gut strings (including the G!) with no after-windings and the strings secured not by loops but each only by a simple knot on the underside of the tailpiece; or a similar set of plain steel strings again with no after-windings.

The problem is that in reality the frequency of the after-length depends on factors which vary across all four strings. These factors include "dead" non-vibrating regions where the string passes over the bridge and the tail-piece, and windings on the string which affect its weight over part of its length and therefore its frequency of vibration. The "dead" region depends on the thickness and stiffness of the material, and obviously varies across the strings, so the true vibrating length varies from one string to the other. The "dead" region problem is compounded by a loop end E string with two tensioned wire strands extending from the prong to the string winding (see the photo in Fox's post of Dec 24) - where does the "dead" region now start and end, or is there more than one?

Adding further complexity to this mixture of effects is the behavior of the bridge, which is a vibrating, frequency-generating structure in its own right. I'd like to see the differential equations for the overall structure of strings, bridge and tailpiece, if anyone has worked them out!

This discussion has been archived and is no longer accepting responses.

Violinist.com is made possible by...

Violinist.com Holiday Gift Guide

Dimitri Musafia, Master Maker of Violin and Viola Cases

International Violin Competition of Indianapolis

Johnson String Instrument/Carriage House Violins

Subscribe

Laurie's Books

Discover the best of Violinist.com in these collections of editor Laurie Niles' exclusive interviews.

Violinist.com Interviews Volume 1, with introduction by Hilary Hahn

Violinist.com Interviews Volume 2, with introduction by Rachel Barton Pine

December 21, 2016 at 04:28 AM · Differences? Yes, lots of them!

Are you going to notice them? Unlikely!

Hill Style fine tuners are said to be the lightest finer tuners, and also allow you to have the proper afterlength on the string. They do have the little hooks that can cut through strings if you don't carefully file it down to round the edges.

Wittner fine tuners are big and bulky adding weight and changing the string's afterlength. Most can use either loop or ball strings.

And then you have these torture devices.... I actually never met anyone who uses them on a violin. Maybe they can double as wolf eliminators? They've got to add a bunch of weight on the string! And mess with the afterlength.

Tailpieces with built-in fine tuners that most people can afford are said not to have the same acoustic properties of wood but otherwise are wonderful at keeping weight and afterlengths happy. Cellists love them!